Electronic industry waste gas treatment solutions |

|

|

| Publisher: Wuxi Bonrxin Environmental Technology Co., Ltd. Release time:2018-9-3 15:49:35 shut down:2329 shut down |

|

|

|

The process of painting and drying in the electronics factory is the main link in the production of exhaust gas. Samples are collected at the outlet of the exhaust pipe of the painting or painting workshop, the inlet and outlet of the exhaust VOCs treatment facility, the coating plant installation area, the paint booth, the upper boundary of the factory, and the downwind of the factory. The pollutants include toluene, xylene, and three. Toluene, butyl acetate, methyl isobutyl ketone, isopropanol, cyclohexane, and the like.

By identifying the species types of VOCs produced in different processes during the coating process of different products, the number of VOCs produced by the coating process is large, and some 8~10 species, of which aromatic hydrocarbons account for the largest proportion, VOCs of different links. Species types are not identical.

Since the electronics industry involves many different production processes, the resulting exhaust pollutants vary widely and require targeted solutions. You can directly inquire, and Zhaoxing will arrange professional technicians to visit your factory.

Waste gas treatment plan

The waste gas treatment of the electronics factory shall be carried out for the purification of organic waste gas generated by processes such as electroplating, etching, oxidation, immersion gold, immersion tin, spray tin and frying stick.

For the organic waste gas produced, the common purification methods are as follows:

a. activated carbon adsorption method;

b. catalytic combustion method;

c. spray absorption tower;

d. photocatalytic oxidation;

e. low temperature plasma purification;

Since any single purification technology is used alone, there are certain technical defects and cannot meet the requirements for compliance. Therefore, a combination of various purification technologies is relatively common. In addition to the catalytic combustion method, other treatment technologies are used more frequently, and we will provide you with targeted combined treatment solutions based on the situation of the site investigation.

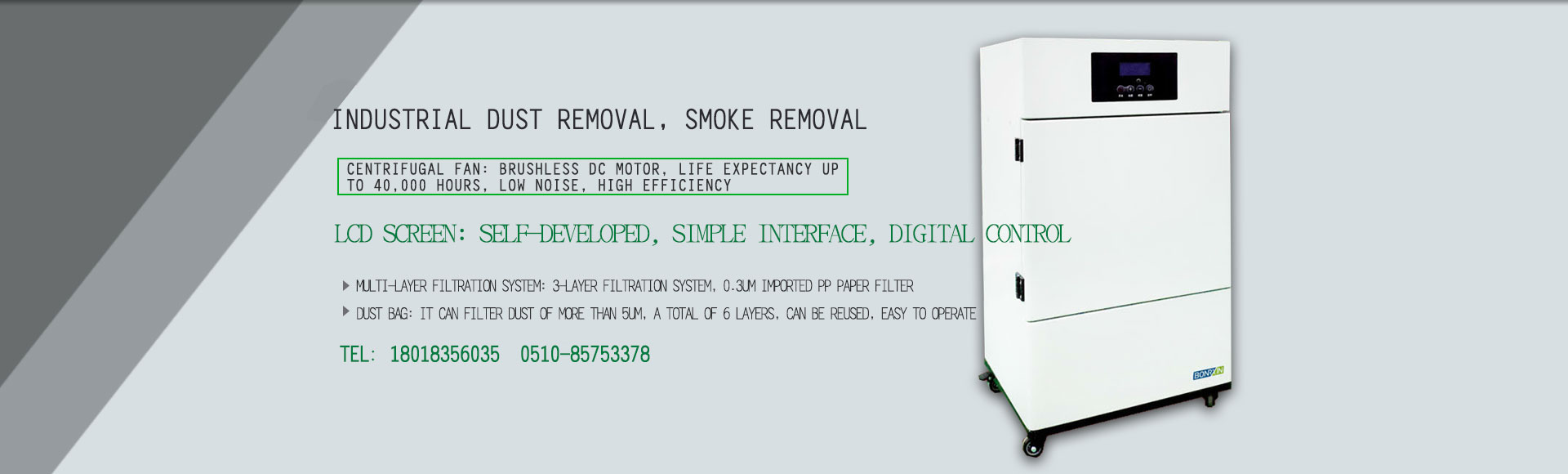

Smoke Processor BCB-350W-YF

This product is a purification product for dust, odor, toxic and harmful gases generated by laser marking, laser engraving, cutting, grinding and other occasions. Has a good dust filtration, odor treatment effect. Multi-layer filter unit is used, including 5um filter bag, 0.3um PP filter core and activated carbon filter. It can effectively filter and intercept all dust-contaminated particles on 0.3μm, and the filtration purification rate can reach 99.70%. And the activated carbon filter core adsorbs some toxic and harmful gases, such as benzenes, ketones, alcohols, alkanes and their mixed organic waste gases. The clean air treated by the purification equipment can be directly discharged indoors. This product is flexible and can be used with filter core according to the use environment; if it is used to handle large dust environment, it can be used separately with filter bag and PP filter core combination; when dealing with large odor environment, it can use 4 layers of activated carbon plus filter bag combination.

Features

1. Centrifugal fan

The brushless DC motor centrifugal fan has a longest life of up to 40,000 hours and requires no maintenance reliability. Low operating noise, high speed, high wind pressure and high performance.

2. LCD

Independently research and development of microcomputer LCD screen, using programmable single-chip software to achieve digital control; simple interface, operating parameters at a glance. Automatically detect the working state of the fan, and automatically alarm the pipe gambling plug and filter saturation. Low pressure control greatly improves safety.

3. Dust bag

This product uses a large-capacity dust bag to filter dust above 5um. A total of 6 layers, can accommodate a large number of dust particles. When the dust collection reaches a certain amount, it can be taken out and cleaned up and then used. Convenient and simple, saving time and effort.

4. Multi-layer filtration system

This product uses a total of three filters, which are 5um dust bag for dust filtration, 0.3um imported PP paper filter, and activated carbon filter. Filtration layer by layer according to filtration precision, and finally achieve complete filtration of dust above 0.3um. Finally, the last toxic and harmful gas adsorption is carried out by the high-efficiency activated carbon filter for the air level containing no dust above 0.3um, so as to achieve the final clean air discharge. |

|